The Indonesian Wood Export Regulation

September 27, 2022

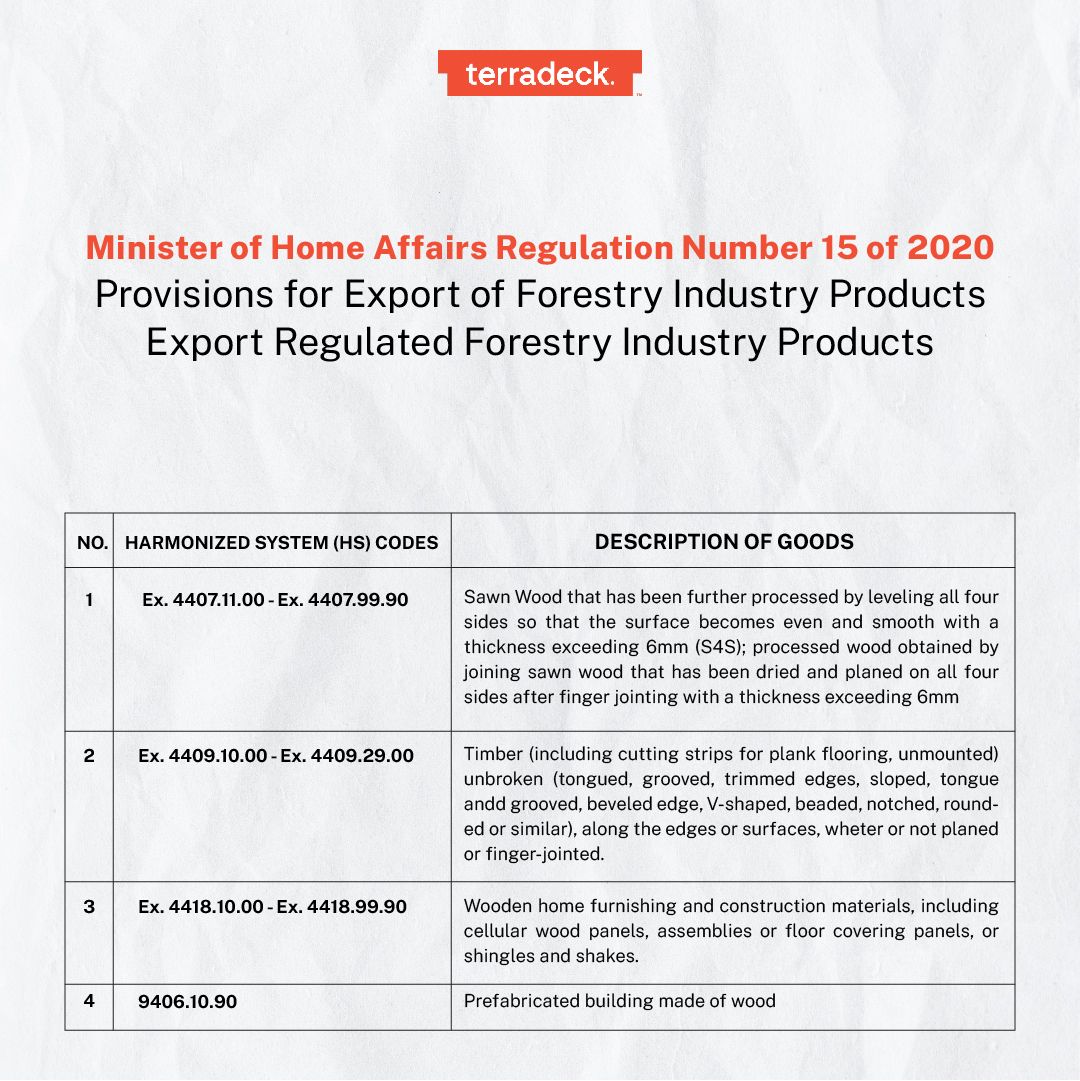

Technical criteria used to determine processed wood (S4S & E2E), Finger Jointed, Flooring, and Decking which can be exported.

Referring to government regulations, Indonesian sawn timber must at least be surfaced on four sides (S4S) for export. What are the rules? S4S wood products have been sawed, dried, and leveled on all 4 sides, resulting in a surface that is even and smooth with a cross-sectional area of no more than 4,000 mm2 (6.2 in2).

Aside from the S4S form, there are other derivative forms such as E2E and E4E that we have summarized based on government regulations.

Size and Degree of Processing

S4S Which includes HS.4407; Processed wood products that are flattened on all four sides so that the surface becomes even and smooth.

Derived from merbau wood provided that the cross-sectional area is not more than 10,000 mm2 (15.5 in2).

Derived from other than Merbau wood provided that the cross-sectional area is not more than 4,000 mm2 (6.2 in2).

E2E which includes HS.4409 processed wood products derived from S4S which are curved at two angles (E2E) or four (E4E) With a minimum bend Angle of 3 mm (0.1 in) (R3).

Derived from merbau wood provided that the cross-sectional area is not more than 10,000 mm2 (15.5 in2).

Derived from other than merbau wood provided that the cross-sectional area is not more than 4,000 mm2 (6.2 in2).

Finger jointed which includes HS.4407 processed wood product produced by joining sawn wood that has been dried and planned on all four sides after the finger jointed process, provided that the length of each jointed chip is not more than 1,000 mm2 (1.55 in2).

Flooring which includes HS.4409 has a thickness of not more than 35 mm with a cross-sectional area of not more than 7,000 mm2 (10.85 in2) in the form of tongue and groove, groove and groove, or shiplap, with the following conditions:

The width of the deep groove is not more than 50 mm (2 in) and the height of the tongue or shiplap is at least 2 mm (0.08 in).

More than 50 mm (2 in) to 100 mm (4 in) wide with deep grooves and a tongue or shiplap height of at least 3 mm (0.1 in).

More than 100 mm (4 in) wide with deep grooves and a tongue or shiplap height of at least 5 mm (0.2 in).

Decking that includes HS.4409 has a thickness of not more than 45 mm (1.7 inch) and a cross-sectional area of not more than 9,000 mm2 (13.9 in2), provided that:

From Merbau, Keruing/Apitong, Kempas, Bengkirai, Kapur, Ulin and Balau Wood species.

Not more than 20 mm (0.7 in) thick having in Reeded/Groove on the sides a width of at least 1.5 mm (0.05 in).

More than 20 mm (0.7 in) thick up to 35 mm (1.4 in) deep Reeded/Groove on the wide side of at least 3 mm (0.1 in).

More than 35 mm (1.4 in) thick up to 45 mm (1.7 in) deep Reeded/Groove on the wide side of at least 5 mm (0.2 in).

If there is a Reeded/Groove on two sides, the depth of the Reeded/Groove is the sum of the two sides.

At least half the width of the surface must be reeded or given two grooves with a proportional distance along the length of the wood.